Description

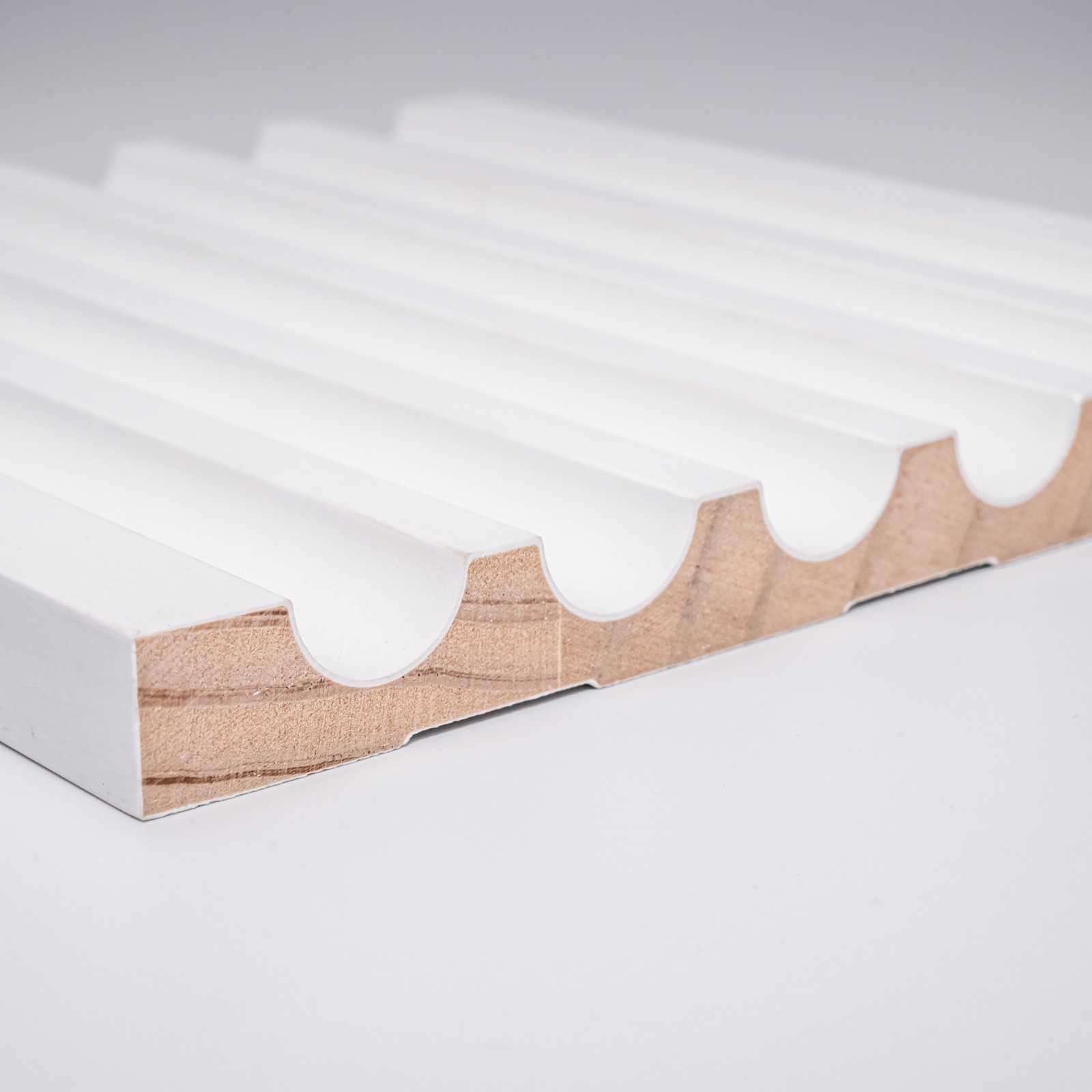

Beach house crown molding is crafted with the highest quality materials to ensure durability, aesthetic appeal, and resistance to coastal environmental factors. Made from premium-grade hardwoods such as white oak, mahogany, or poplar, as well as moisture-resistant MDF and high-density polyurethane, our house crown molding is designed to withstand the humidity and salt air prevalent in beachfront properties.

Each house crown molding piece undergoes a meticulous quality control process, ensuring a smooth finish, precise dimensions, and impeccable detailing. The materials are selected for their ability to resist warping, cracking, or swelling due to temperature and humidity fluctuations, ensuring long-lasting performance. Our polyurethane and PVC options provide an excellent alternative to traditional wood, offering enhanced resistance to moisture and insects while maintaining the elegant look of traditional crown molding.

Add beauty and interest to any room with luxury crown molding. luxury crown molding includes a complete line of decorative moulding for any room or project: base, fluted casing, chair rail, crown, general purpose, and door and cabinet trim. luxury crown molding is available in random and eight foot lengths allowing for endless possibilities. luxury crown moldinginstalls the same as traditional moulding and is made from solid pine, which can be finished with paint, stain, or varnish.

Production Process

Production Process

Our traditional crown molding is manufactured using advanced techniques that combine craftsmanship with precision engineering. The production process involves several key stages:

Material Selection: High-quality hardwoods, moisture-resistant MDF, or durable polyurethane are carefully chosen for their performance and aesthetic qualities.

Precision Cutting & Molding: Using state-of-the-art CNC machinery, each piece is cut with precision to ensure consistent dimensions and intricate detailing.

Surface Treatment & Finishing: House crown molding undergo sanding and priming to achieve a flawless surface, while polyurethane options receive a factory-applied finish for easy installation.

Quality Control & Inspection: Each piece is rigorously inspected to meet the highest standards of craftsmanship, ensuring smooth surfaces, uniform profiles, and structural integrity.

Packaging & Delivery: The finished products are securely packaged to prevent damage during transport, ensuring they arrive in pristine condition ready for installation.